Collect VOC

Collect VOC

INNOVATION ROAD MAP

A collaborative go-to-market Journey need product management, sales,brand marketing, design, development,planning department seamless work together to deliver innovative projects.

CONCEPT EXPLORATION

concept stories, proposed seasonal liner plan,identify advanced projects&clarity around the ‘win’, align go-to-market spend allocation, design language,technical input&competitive analysis, align vendors&capacity.

BRIEF FINALIZATION

Goal: confirm and share brief, official sign off, initiate go-to-market planning,official start of design phase, develop project charter for project feasibility in terms of cost parameters,timeline&resources

Planning: initial forecast and sourcing allocation

CONCEPT REVIEW

Align on 2D and rapid prototype design direction, review 1st samples off prototype tool, confirm 2D design direction.

Thorough merchandising decision in relation to business objectives, channel strategy, color-material and pricing strategies.

DEVELOPMENT

FMEA,DFM, Mold flow analysis, tooling, testing, certification, Graphic development, packaging,samples signed-off, tooling planning, pilot run.

COMMERCIALIZATION

sales samples, and manufacturing preparation, BOM, Costing, SOP, ERP.

GO-TO-MARKET,PO

Release PO, work with supply Chain on 1st delivery.

Product in warehouse ready to ship to customer.

Details action plan as following:

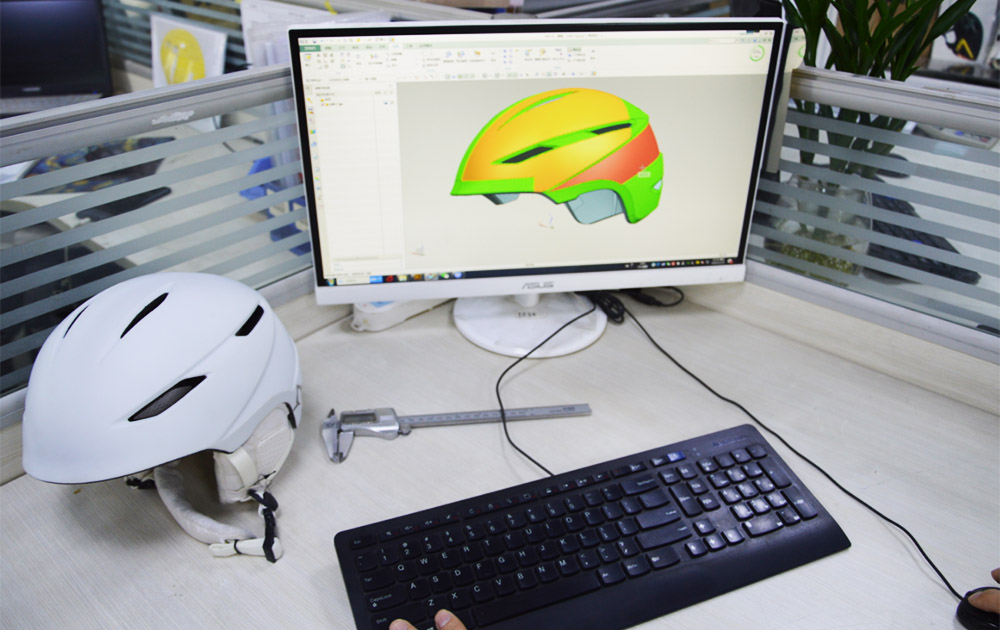

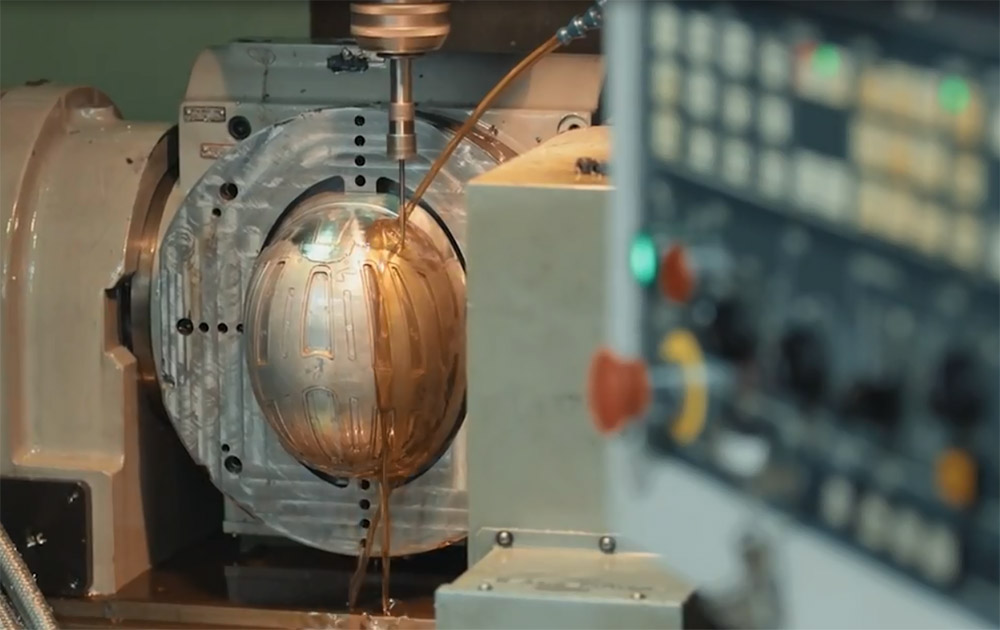

Collect VOC (voice of customer) to get customer expectation then apply QFD(quality function depolyment) to identify key features, inspire concept to protype it, finalize concept development by concept optimization. 3D modeling meanwhile have FMEA and DFM analysis. Get precision EPS tool and vaccuum forming tool by advanced equipment including wire electrical discharge machinning and CNC cutting.

Create impact road map according to respective standard, mold liners in specified density,use calibrated Cadex test device to do in-house test by skillful lab techinican . Certify each model by well-recognized cert. lab.

Make work instruction and SOP ( standard operation procedure) with defined manufacturing tolerance. Make Process control plan to ensure high quality. Visualize development milestone by scrum board, closely follow development by using OKR list, daily stand-up meeting and Gantt chart schedule.

Commercialize each project on time at cost with high quaity.

Concept - 2D - Clay

QFD

Technical input & competitvie analysis.

Concept finalization, product design.

Design for tooling , testing and costing.

Production feature definition

Surface modeling - Rapid prototype

Scanning clay.

Surface modeling.

High quality rapid prototyping.

Review design language.

DFM & DFMEA

CNC tooling

Modex Flow Analysis.

Optimize tool configuration

Precision tooling.

Design for manufacturing, design for costing analysis.

Visualize tooling schedule and milestones.

Sampling and testing

Fully-owned test facilities.

Well understand test Standards.

Create impact roadmap and draw test line.

Consolidate test report and provide professional analysis.

Pilot run and quality review.

Manufacture

Fully owership of entire supply chain.

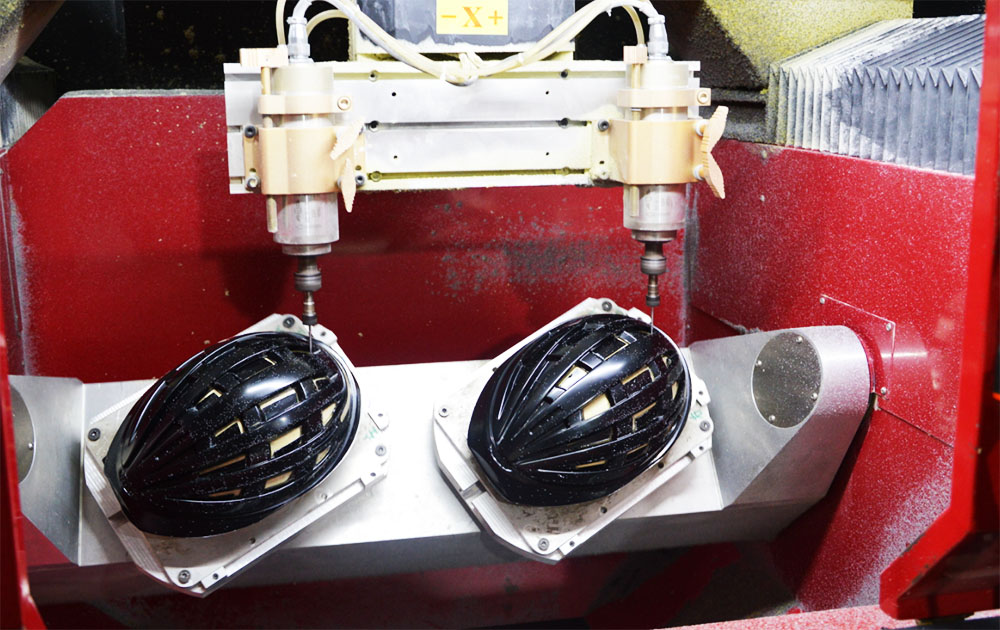

Robot precision trimming.

SOP and Process Control plan to ensure quality concsistency

On time delivery

Quickly response, Customer-oriented service.